Plastic Material Shrinkage Rate

1. Common Plastic Engineering Materials and Shrinkage Rates:

- ABS: 0.5% (Super Tough Plastic)

- PC: 0.5% (Bulletproof Glass Plastic)

- PMMA: 0.5% (Organic Glass)

- PE: 2% (Polyethylene)

- PS: 0.5% (Polystyrene)

- PP: 2% (Polypropylene)

- PA: 2% (Nylon)

- PVC: 2% (Polyvinyl Chloride)

- POM: 2% (Acetal)

- ABS+PC: 0.4%

- PC+ABS: 0.5%

- Engineering Materials: ABS, PC, PE, POM, PMMA, PP, PPO, PS, PET

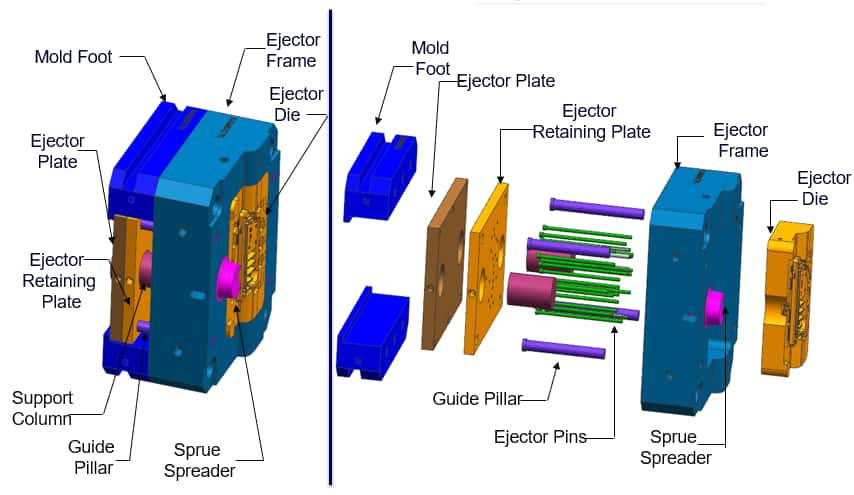

2. Major Systems in Molds:

- Gating → Ejection → Cooling → Forming → Venting

3. Considerations in Mold Design:

- (1) Uniform wall thickness and adequate draft angles.

- (2) Gradual transitions and smooth corners to avoid sharp edges.

- (3) Gates and runners should be wide, short, and positioned considering shrinkage and cooling; cold slug wells may be necessary.

- (4) Mold surface should be smooth with low roughness (preferably below 0.8).

- (5) Adequate venting holes and slots to expel air and gases.

- (6) Except for PET, wall thickness should not be too thin, generally not less than 1mm.

4. Common Defects in Plastic Parts:

- Short shot → Flash → Bubbles → Shrinkage → Weld lines → Black spots → Streaks → Warping → Delamination → Peeling

5. Common Plastic Mold Steels:

- 45#, S50c, 718, 738, 718H, 738H, P20, 2316, 8407, H13, NAK80, NAK55, S136, S136H, SKD61

6. Steel for High Gloss Polishing:

- Commonly used high-hardness heat-treated steels, such as SKD61, 8407, S136.

7. Mold Base Structures:

- Clamping plate → A plate → B plate → Spacer block → Guide pin → Ejector plate → Ejector retainer plate → Bottom plate

8. Basic Types of Parting Surfaces:

- Flat → Inclined → Curved → Vertical → Arc-shaped

9. How to Hide in UG:

- Ctrl+B or Ctrl+Shift+B

Mold Processing Equipment and Techniques

10. Mold Processing Machinery:

- CNC machining center → Lathe → Milling machine → Grinding machine → Drilling machine

11. What is 2D and 3D?

- D stands for Dimension. 2D refers to two-dimensional planes, and 3D refers to three-dimensional space. In molds, 2D usually refers to CAD drawings, and 3D refers to three-dimensional models.

12. Default Precision in Pro/E and UG:

- Pro/E default precision: 0.0012mm, UG default precision: 0.0254mm.

13. Top Four Global Mold Base Manufacturers:

- Germany: HASCO, Japan: FUTABA, USA: DME, China: LKM.

14. Default Text Height in CAD:

- CAD default text height: 2.5mm.

15. What is a Shut-off and a Core?

- Shut-off refers to the mating surface parallel to the PL surface, and core refers to the mating surface not parallel to the PL surface.

16. Relationship between Tiao and Si:

- Both are units of length. Tiao is used in Taiwan, 1 Tiao = 0.01mm; Si is used in Hong Kong, 1 Si = 0.01mm. Therefore, 1 Tiao = 1 Si.

17. What is a Pillow Block?

- The edge of a shell plastic part often has notches for installing accessories, forming a pillow-shaped parting surface called a pillow block.

18. What is a Crater?

- The reduced material at the base of a boss, resembling a volcanic crater, is called a mold crater.

19. What is a Core?

- Core refers to the mold insert, commonly used in Hong Kong.

20. What is a Tiger Mouth?

- Tiger mouth, also known as a positioning block, is used for limiting positions.

21. What is Layout?

- The arrangement of products on a mold is called layout.

22. What is a Cavity?

- The hollow part of a product on a mold is called a cavity.

23. What is a Rib?

- The ribs on a product are called ribs.

24. What is a Boss?

- The columns on a product are called bosses.

25. What is Clearance?

- The gap on a mold is called clearance.

26. What is a Hook?

- The connecting hooks on a product are called hooks.

27. What is EDM Texture?

- The texture left after EDM (Electrical Discharge Machining) is called EDM texture.

28. What is a PL Surface?

- PL surface, also known as the parting surface, is the contact surface between the front and rear molds when closed.

29. What is a CNC Machining Center?

- CNC milling machines and machining centers.

30. What is a Copper Electrode?

- EDM often uses easily machinable copper as the discharge electrode, called a copper electrode or simply electrode. Copper electrodes are generally divided into rough, semi-finish, and finish electrodes, with finish electrodes also known as precision electrodes.

Copyright ? 2024 Shenzhen Aoerte Plastic Technology Co., Ltd.. All rights reserved

Site map

Comment

(0)